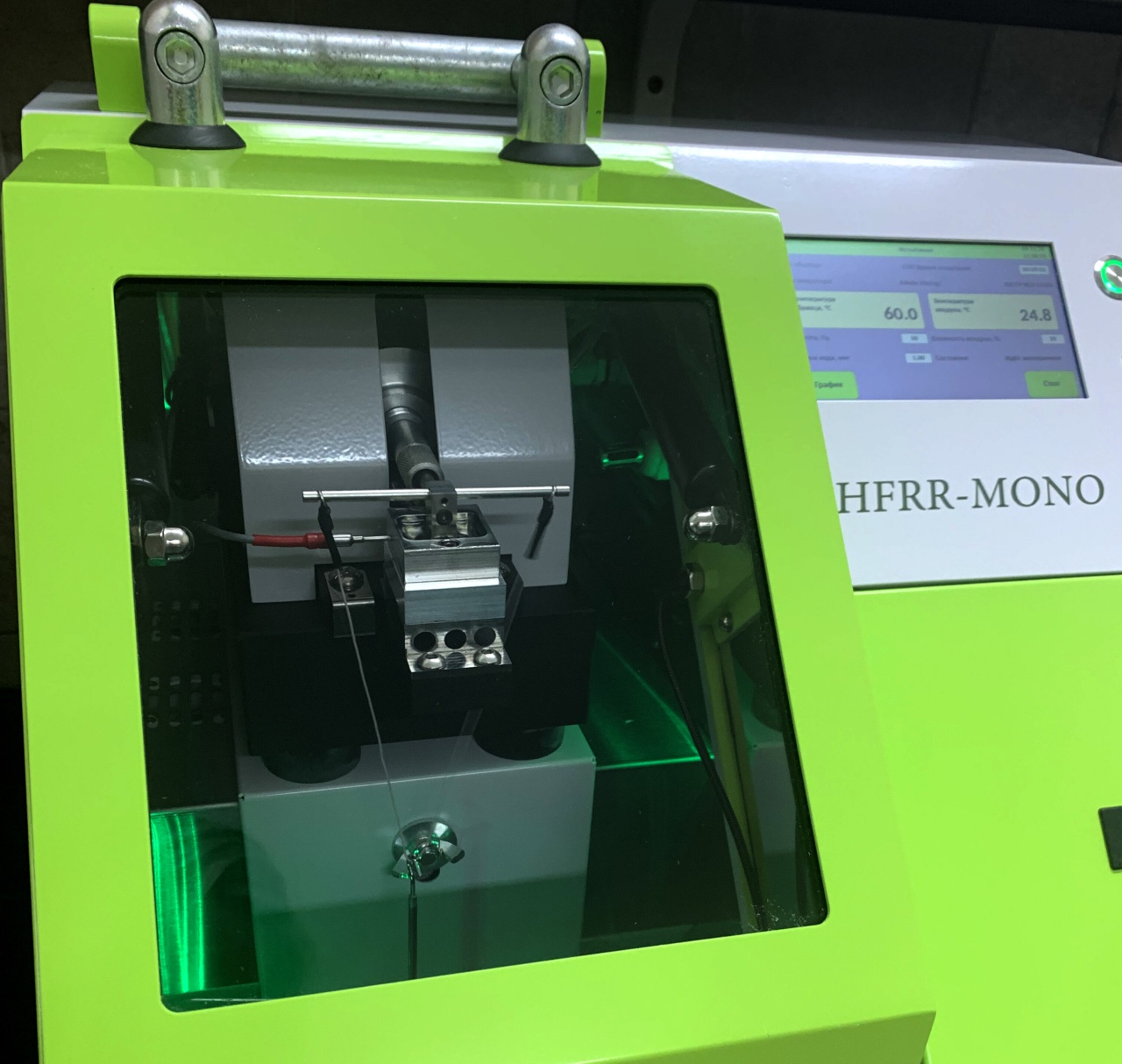

HFRR-MONO

Automated diesel fuel lubricity test system

European CE Certificate

Confirms that the products of the Techno company comply with all the requirements of the directives and standards of the European Union, and they are absolutely safe for the health of both consumers and the environment.

The CE certificate of conformity is issued on the basis of tests carried out in independent laboratories and certification bodies of the EU and gives the right to apply appropriate labeling to products. This marking provides an opportunity to sell your goods on the territory of the EU countries because it is a guarantee of the quality and safety of our products.

HFRR-MONO

Monoblock: control unit, climate chamber, test module, air preparation unit, computer, storage chamber for balls-plates in a single case.

We know that many laboratories have problems with space, so we tried to make the instrument compact. The device has relatively small dimensions and weight, so it can be easily placed on a regular table.

Automatic maintenance of the set temperature and humidity in the climate chamber

The device has the ability to automatically maintain the temperature and humidity without operator intervention. The climate chamber has humidification, dehumidification, cooling and heating functions. The innovative dehumidification and cooling system is small in size and does not require maintenance throughout its life.

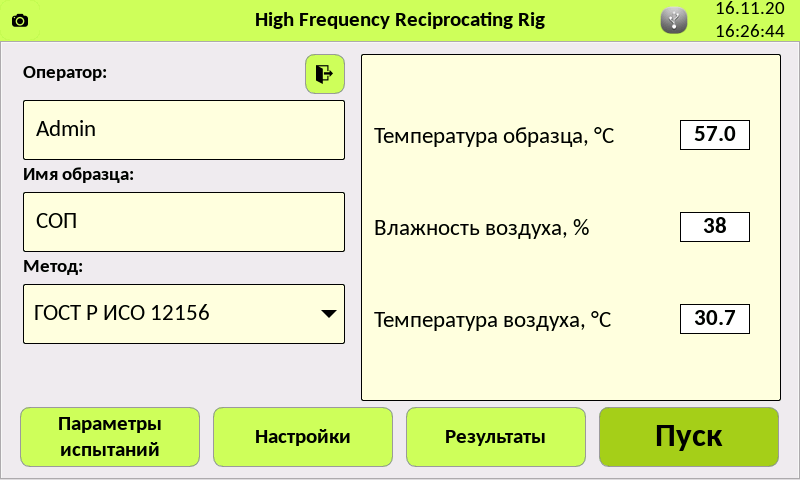

Integrated data processing and color touchscreen display

The built-in data processing system automatically controls the process and analyses the test results. This system allows you to build graphs with a choice of parameters and scaling, and also automatically calculates WS1.4. The HFRR-MONO is capable of remote firmware updates. Data export to LIMS can be performed after analysis is complete, or data can be saved to the internal memory for up to 2000 experiments.

The ability to carry out several tests on one plate by changing its position in the device (for research purposes)

The plate holder design allows multiple tests to be carried out, which can significantly help save on consumables.

Test procedure

The HFRR High Frequency Reciprocating Rig (HFRR Reciprocating Rig) is based on devices that have been used for many years in the Tribology (Friction and Lubrication) Department of the Faculty of Engineering at Imperial College London.

Systems of this type are used to determine the lubricity of a sample during slow cyclic sliding. The HFRR system has proven particularly useful in assessing the lubricity of diesel fuels.

The HFRR system uses an electromagnetic motor to provide low-amplitude oscillations of a moving specimen pressed against a stationary specimen. The amplitude and frequency of these vibrations can be changed. In this case, the friction force between the samples and the voltage drop at the point of contact between them are measured.

The lower, fixed specimen is secured in a small tray containing the lubricant to be tested. The lower specimen holder is equipped with an electric heater. Testing specimen of various shapes is possible. The reference materials for testing diesel fuels are a 6 mm ball for the upper specimen and a 10 mm disc for the lower specimen.

The HFRR system has the following advantages over other methods of lubricity assessment:

- Good repeatability and reproducibility of measurement results;

- The possibility of assessing the wear spot of standard samples using only one measurement;

- A very small amount of lubricant is sufficient, so testing of experimental lubricating fluids is possible;

- The ability to observe the formation of a thin film because of surface additives through the change in voltage at the point of contact;

- The ability to measure sliding friction at large amplitudes of specimen movement, as well as wear due to friction using the same system.

Specification

- Methods

- ISO 12156, ASTM D7688, ASTM D6079, IP 450

- Frequency

- 10…200 Hz

- Stroke length

- 20 μm…2 mm

- Load

- 0…1000 g, using weights in increments of 100 g.

- Maximum friction force

- Amplitude dependent, maximum 10 N

- Temperature

- the ambient… +150 °С

- Ball requirements

- 6 mm diameter

- Plate requirements

- 10 mm diameter, 3 mm thickness

- Condition monitoring system

- Multilevel access, control of humidity and air temperature in the climatic chamber, control of the sample temperature sensor installation, door position control, calculation of WS1.4

- Power supply

- 100-240V, 50/60 Hz, 320 W

- Heaters

- Two 24 W cartridge heaters

- Climate chamber characteristics

- Humidification up to 80%

Dehumidification down to 30%

Heating up to 35 °С

Cooling down to +15 °С - Custom functions

- 7 inch color touch screen

Storage for up to 2000 experiments

The ability to transfer data to LIMS

Keyboard and mouse connectivity

Barcode scanner connectivity - Connections

- 1 × Ethernet, 4 × USB, Bluetooth, wifi

- Accessories

- set of equipment for determining the lubricity of gasoline, printer, standard solution, ball-plate test specimen

- Dimensions WxDxH

- 550x500x850 mm excluding the wear spot measurement system

- Weight

- 60 kg